How to choose the material grade of silicon steel lamination for stators & rotors?

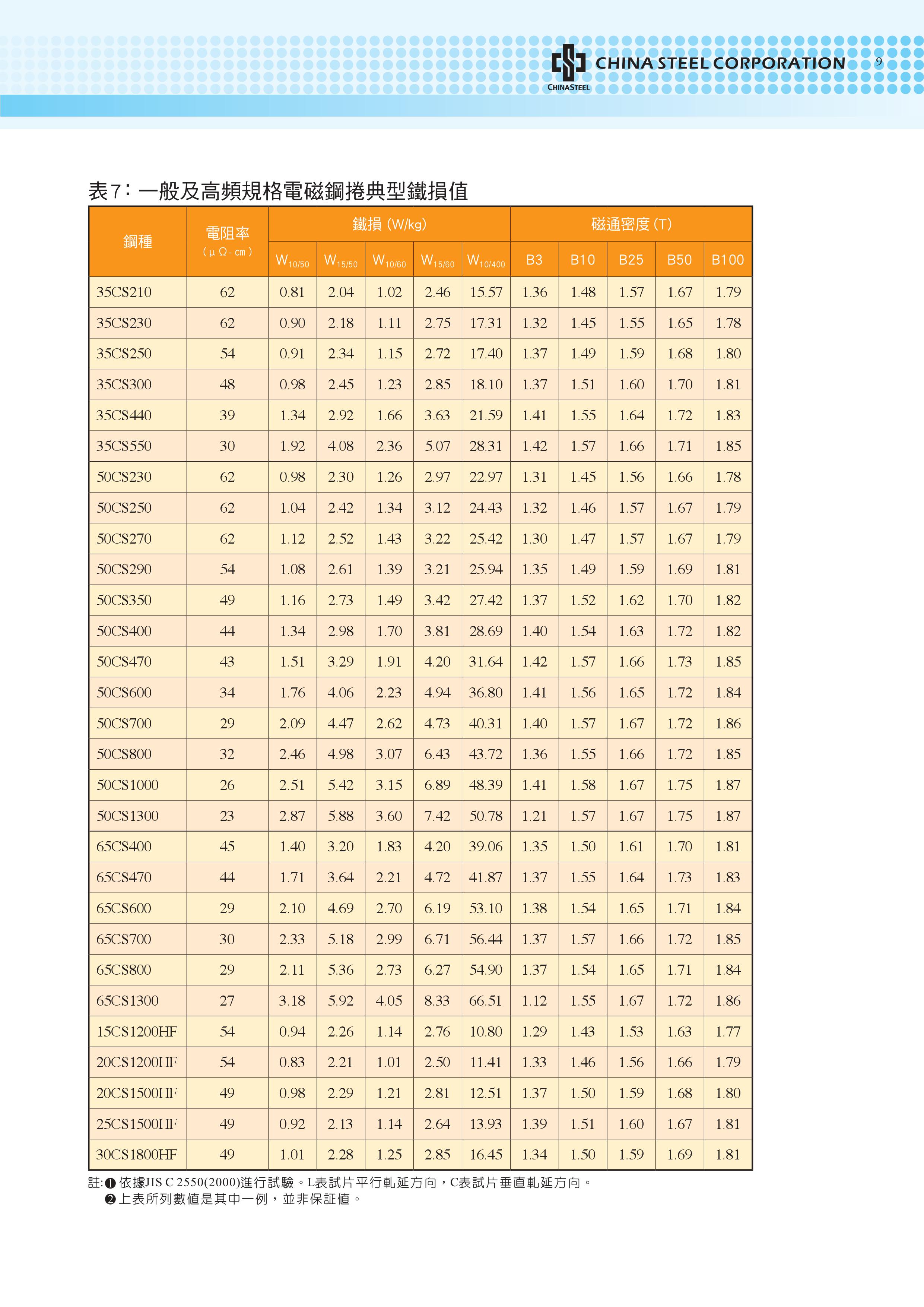

There are different magnetic coil manufactures in the world. The key point to choose the suitable material grade is "iron loss". Normally, we suggest our customers to use 50CS1300. The iron loss is 5.88W/kg. For pumps, we suggest to use 50CS800, which the iron loss is 4.98W/kg.

Note: The unit is W15/50, which means maximum specific total loss at a peak magnetic flux density of 1.5T and a frequency of 50Hz.