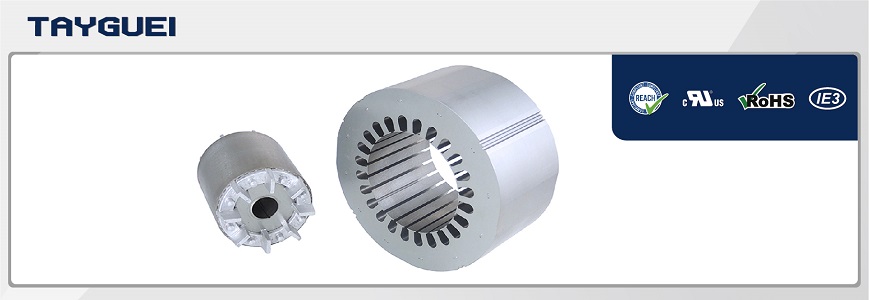

Stator Rotor for Blower Motor

Induction Asynchronous Blower Motor Stator Rotor silicon steel lamination, stator winding

Speaking of compressing air and convey air, there are three types: fan motor, blower motor and compressor motor. Generally speaking, fan motor aims on transporting air, compressor motor aims on compressing air, and blower motor combines both features of fans and compressors. Blower motors can be equipped with fan motors or compressor motors to develop exhaust fans or vacuum pumps.

Application:

- Compressing and conveying air are blower motors’ typical functions. Under certain pressure range, blower motors can be widely used. The air fluent is usually 0.5 ~ 800 m³ /min, maximum 1,400 m³ /min. Mostly, blower motors are designed for air blowers, and applied for construction, electricity, smelting, petrochemical industry, mining, harbors, food industry…etc. Blower motors can also be used for conveying other types of air, such as H, O2, CO, CO2, H2S, CH4, C2H2 and gas. Ranging from 1 ~ 3HP.

Features:

- Comparing with piston compressors, there are no air valves in blower motors. Blower motors are durable, and able to be operated at high speed. The air flow is stable and no need to equip with gas tanks. Due to blower motors are designed for outputting air, air flow is stable under certain RPM. The vibration is small. Not only impellers but also between shell and walls, there is gap. Therefore, blower motors can convey air without oil. With oil-free advantage, it’s much safer to convey powders. Furthermore, blower motor is much efficiency with no mechanical friction. The construction of blower motors is simple and easy to produce. Users can operate the easily. The maintenance period is long and low cost.

Meet UL regulations:

- Tayguei is a professional manufacturer of stator rotor lamination nearly 40 years. TG11456, TG14075, TG16080 and TG16088 are for blower motors. Those are designed for high RPM, all 2 poles. They are standard sizes to fit in IEC (the International Electrotechnical Commission) regulations. Within IEC, there are standard frame numbers to let motor designers to refer to the related size of stator rotor. If your motor meet with IEC regulation, you can easily find the suitable stator rotor lamination from us.

Tolerance:

- We can control the tolerance to make stator smooth and accurate. Please understand the tolerance differs from different material of silicon steel lamination and design of mold. Usually, it is within 0.03mm-0.05mm. Our material is directly from China Steel. As one of the leading silicon steel lamination manufacturer in the world, the quality of laminations is guaranteed, China Steel is also the supplier for Telsa Automotive in Taiwan. Certainly, there are different grades of laminations for choosing by various design.

IE3 / IE4 Efficiency:

- We are proud to claim that motors using our stator rotor passed the IE3/IE4 testing in UL laboratory. Our material is directly supplied from the top supplier, China Steel. With correct design and our rich experience on mold developing, we can guarantee the quality. We also have a subsidiary company for motor in Taiwan. We have the ability to develop new motor, and do the OEM/ODM business. As to the details, please contact us for further discussion. It would save time, if you could provide us with the drawing of stator rotor in advance. If you also need die aluminum casting, please also provide the drawing of your aluminum injection way.

114x56 mm Stator Rotor Lamination for Two Poles High Efficiency Motor

TG11456

TG11456 is mostly applied for industrial motors, water pump motors, blower motors, sawmill...

Details140x75 mm Stator Rotor Lamination for Two Poles and Six Poles High Efficiency Motor

TG14075

By using TG14075, you can reach low temperature, low current and high efficiency. This stator...

Details160x80 mm Stator Rotor Lamination for Two Poles Motor

TG16080

With 2 types of rotors for options, TG16080 is square shape and mostly applied for power wood...

Details160x88 mm Stator Rotor Lamination for Two Poles High Efficiency Motor

TG16088

With unique design of rotor, TG16088 is round shape and mostly applied for industrial motors,...

DetailsStator Rotor for Blower Motor | IEC/NEMA Stator & Rotor Manufacturer | TayGuei

Located in Taiwan since 1984, TAYGUEI INDUSTRY CO., LTD. has been a stator and rotor manufacturer in the stamped parts industry. Their main stator rotor products include, Stator Rotor for Blower Motor, rotors, stators, motor cores, motor parts, fan motors, silicon steel lamination, rotor lamination, laminated stators, intelligent motors and servo motors, which are sold to over 15 countries.

With almost 40 years experience in standard dimension and customization service. We are expertise in mould development and maintenance that guarantees our high quality products. The main service philosophy is COMPLETE YOUR MOTOR. TayGuei believes helping our client to produce a better motor is priority than any other else. Stator and rotor stamped from high grade steel, 3µm precision, long service life, low power consumption, excellent efficiency and 3 week lead time.

TayGuei has been offering customers motor stators and rotors, both with advanced technology and 39 years of experience, TayGuei ensures each customer's demands are met.