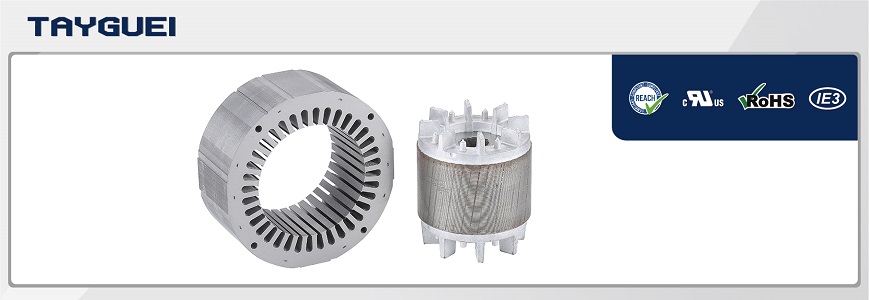

Stator Rotor for Gear Motor

Induction Asynchronous Gear Motor Stator Rotor silicon steel lamination, stator winding

For gear reduction motors, there are 3 types for choosing, TG11070 / TG12575B / TG12575D. Please also be advised that those types are commonly used for European markets. Those stators rotors are matched for IEC regulation. Those are 4 poles for lower RPM. Besides, the number of rotor slots are 44 slots. Since they made from high speed stamping machines, they are designed with inner-lock (riveting). Please note the center hole (for shafting) ranges from φ14 ~ φ22.

Application:

- There are wide usages of gear motors, mainly in governance, mining, construction, blowing motors, elevating machinery…and etc. Let’s make it in easy way to understand. Whenever you need to adjust the speed, you will need gear motors. Nowadays, treadmills, cranes, golf carts….and etc. all are gear reducer’s applications.

Features:

- What’s the feature of gear motors?

- When we talk about gear motors, we usually mean the Gear Reducer Motors. They contain two parts, induction motor and gear box. The main function of gear reducer motor are two points. First, reducing the speed meanwhile increasing the output torque power. Secondly, changing the direction of input power. Gear boxes are used for changing speed, for example, if we use two gears (one big gear & one small gear) to transfer power to another rotating shaft, the gear box is applied to change the speed. Equipped with electromagnetic brake and you can control complex counter-clockwise or clockwise rotation. There are various of speed reduction ratio for options.

Basic models:

- According to functions, allowable torque, transmissions and applications, there are six models as listed below: Helical gear reducer, Bevel gear reducer, Worm wheel reducer, Planetary gear speed reducer, Oblique gear speed reducer and Harmonic gear reducer. Furthermore, we can roughly divide them into 3 types by axes, which are Parallel axes, Intersecting axes and non-parallel & none intersecting axes. At present, the most common types are Helical gear reducers, which are widely used in AC motors.

Advantages:

- Firstly, lower RPM. When machines need low speed, we can use speed reducers to lower the motor RPM. Besides, reducers can solve the un-efficiency problem during rotating in low RPM, and make the motor stable. Secondly, increase torque. There are many ways to increase torque. Some will suggest increase the watt (HP) of motors. However, this will increase the cost of current device and driver. Therefore, the cost of controlling system increase. Besides, the volume of motor become bigger for bigger HP. So we can say the best way to increase torque is to equip with reducer—lower RPM and high Torque. Thirdly, with equipping the reducer, the RPM becomes small, then we are able to position the angle precisely. Finally, increase loading.

Tolerance:

- We can control the tolerance to make stator smooth and accurate. Please understand the tolerance differs from different material of silicon steel lamination and design of mold. Usually, it is within 0.03mm-0.05mm. Our material is directly from China Steel. As one of the leading silicon steel lamination manufacturer in the world, the quality of laminations is guaranteed, China Steel is also the supplier for Telsa Automotive in Taiwan. Certainly, there are different grades of laminations for choosing by various design.

IE3 / IE4 Efficiency:

- We are proud to claim that motors using our stator rotor passed the IE3/IE4 testing in UL laboratory. Our material is directly supplied from the top supplier, China Steel. With correct design and our rich experience on mold developing, we can guarantee the quality. We also have a subsidiary company for motor in Taiwan. We have the ability to develop new motor, and do the OEM/ODM business. As to the details, please contact us for further discussion. It would save time, if you could provide us with the drawing of stator rotor in advance. If you also need die aluminum casting, please also provide the drawing of your aluminum injection way.

140x85 mm Stator Rotor Lamination for Four Poles and Six Poles High Efficiency Motor

TG14085C

TG14085C is applied for 3 phase industrial fan motors. It can reach high efficiency but with...

Details110x70 mm Stator Rotor Lamination for Four Poles and Six Poles Motor

TG11070

TG11070 is mostly applied for industrial motors, reducer motor and oil pump motors. The outer...

Details125x75 mm Stator Rotor Lamination for Four Poles Motor

TG12575B

TG12575B is designed for European market with 125mm diameter. The stator is square shape and mostly...

Details125x75 mm Stator Rotor Lamination for Four Poles and Six Poles Motor

TG12575D

TG12575D is applied for industrial motors, gear motors and air compressor motors with this...

DetailsStator Rotor for Gear Motor | IEC/NEMA Stator & Rotor Manufacturer | TayGuei

Located in Taiwan since 1984, TAYGUEI INDUSTRY CO., LTD. has been a stator and rotor manufacturer in the stamped parts industry. Their main stator rotor products include, Stator Rotor for Gear Motor, rotors, stators, motor cores, motor parts, fan motors, silicon steel lamination, rotor lamination, laminated stators, intelligent motors and servo motors, which are sold to over 15 countries.

With almost 40 years experience in standard dimension and customization service. We are expertise in mould development and maintenance that guarantees our high quality products. The main service philosophy is COMPLETE YOUR MOTOR. TayGuei believes helping our client to produce a better motor is priority than any other else. Stator and rotor stamped from high grade steel, 3µm precision, long service life, low power consumption, excellent efficiency and 3 week lead time.

TayGuei has been offering customers motor stators and rotors, both with advanced technology and 39 years of experience, TayGuei ensures each customer's demands are met.